Business Needs

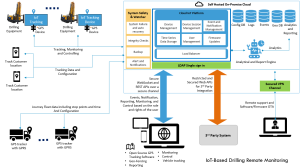

In manufacturing Industry 4.0, it will be always a time critical operation to save the OPEX cost. One of the important parameters is to perform laser marking on the different parts of the machine/object during manufacturing process and it should be automated to save the cost and time of the laser marking.

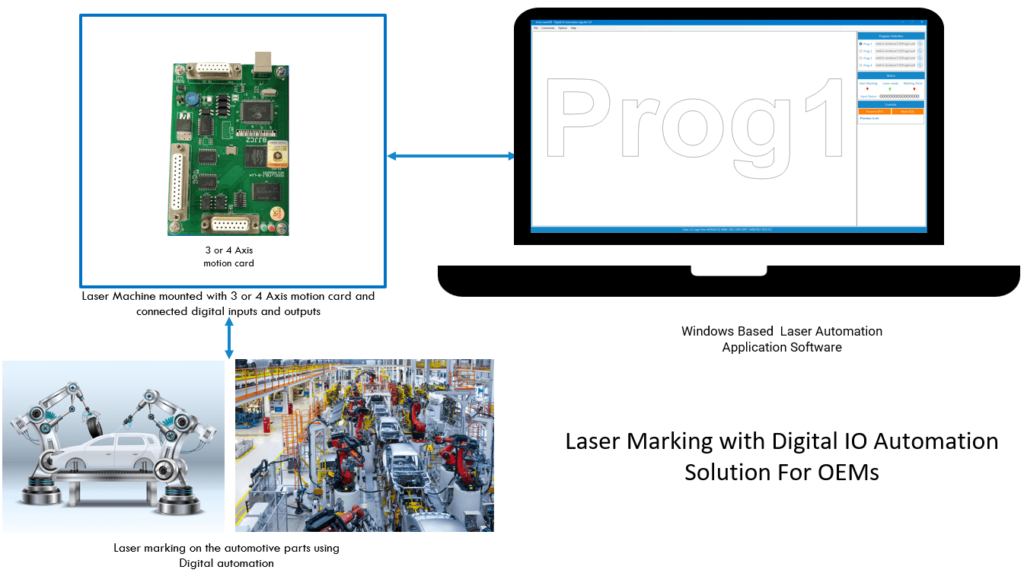

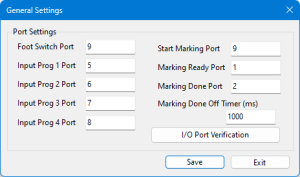

The project includes a system to have connection of Digital I/Os (8 or 16) in between existing PLC/HMI and digital automation laser marking software. It should also support the selection of multiple laser marking programs based on the automated input from the PLC/HMI. Synchronization between PLC and automation software plays a critical part to make smooth and effective laser marking using automation.

Thus, we have designed products with;

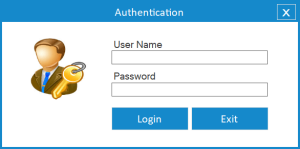

- Customization and white labeling

- Complete Desktop based and Touch based HMI software including control system (using PLC or Controller boards)

- High performance and real-time communication with the machine

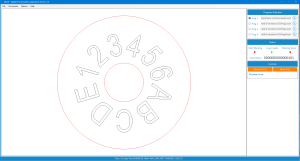

- Multiple Program selection

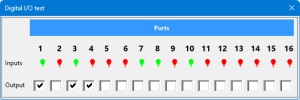

- Support of multiple and configurable IOs

Such soutions are very useful in Automotive domain where autoomation is the key and based on part selection it automatically chose right marking file to perform laser mark at real time.

Solution:

Windows Based BIS HUID Laser Marking Application

- Open wide range of possibilities to make laser marking process automated in large scale production environment

- Multiple program selection based on configured digital input signals

- Configurable input and outputs

- Port test utility to check wire connection between PLC and card to help for the configuration of I/Os

- Synchronization of Start Marking, Laser Ready, and Marking Done signals between PLC and software

3Axis Hardware

- Hardware to communicate with our software application and to drive laser for the marking

OEM and Vendor support

- We provide complete trunkey solution with help of our OEM partner

- we also provide separate 3 or4-Axis hardware and Software solution to other OEM vendors

Benefits

- Open wide range of possibilities to make laser marking process automated in large scale production environment

- Save OPEX cost because of automation of the laser marking and multiple program selection process

- Easy commissioning

Our OEM Partner

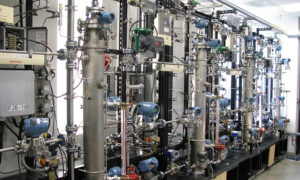

Ouer OEM partner’s Laser Machines mounted with the current solution

OEM Solution

• We provide complete trunkey solution with help of our OEM partner

• we also provide separate 3-Axis hardware and Software solution to other OEM vendors

Faster Time to Market

Our Ready to use hardware, and software stack including Embedded OS, BSP, middleware layer, and reusable application layer and libraries helps to make it faster time to market.

![panel-01[1] panel-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/panel-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![intranet-04[1] intranet-04[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/intranet-041-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![industrial-01[1] industrial-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/industrial-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)