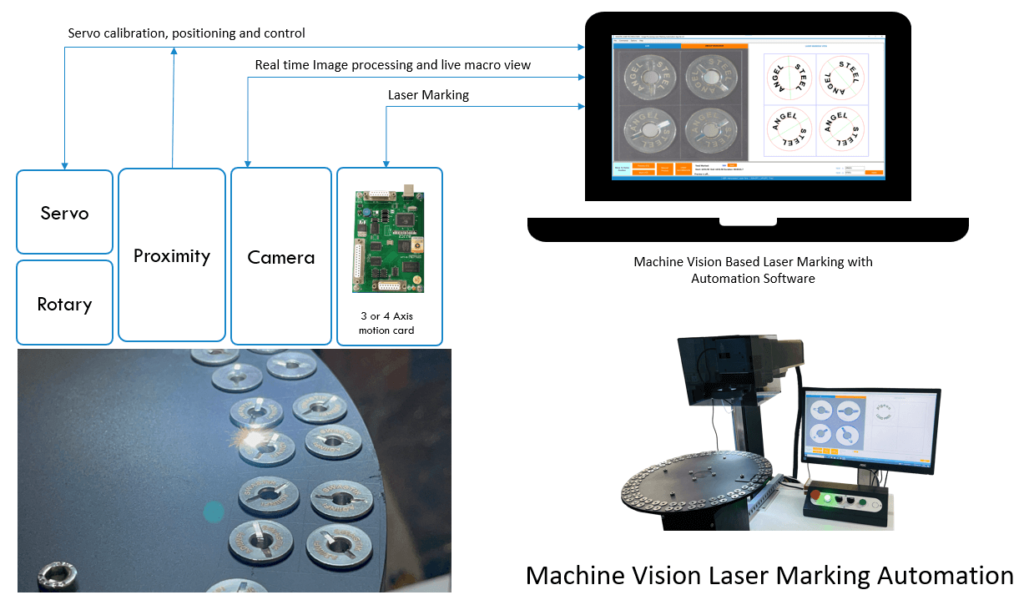

We are proud to announce that we have added a new dimension of Machine (Computer) Vision based laser automation product/solution to our Laser Makring Solution vertical. It has opened lots of opportunities for us to provide customized products, services and solutions to our customers in MACHINE (COMPUTER) VISION, image processing based, and real time operations.

In the ever-evolving landscape of industrial manufacturing, precision and efficiency are paramount. Companies around the world are constantly seeking innovative ways to improve their processes, reduce errors, and enhance product quality. One technology that has been making waves in this arena is machine vision, and its successful integration into the laser marking vertical has been nothing short of transformative.es Here

Laser marking has long been an essential process in industries such as automotive, aerospace, electronics, and medical devices. It allows for permanent and precise markings on a variety of materials, including metals, plastics, and ceramics. However, even with the inherent accuracy of lasers, ensuring precise positioning and alignment has been a challenge. This is where machine vision steps in as a game-changer.

The successful integration of machine vision into laser marking systems has unlocked a myriad of benefits for manufacturers:

Enhanced Precision: Machine vision systems use cameras and image processing algorithms to detect the exact location and orientation of the workpiece, ensuring pinpoint accuracy in marking. This reduces errors and eliminates the need for manual adjustments.

Increased Efficiency: Automation is a cornerstone of modern manufacturing. By automating the positioning and setup of laser marking machines, manufacturers can significantly reduce cycle times and increase productivity.

Quality Control: Machine vision doesn’t just ensure proper marking; it can also be used to inspect the quality of marks in real-time. This reduces the likelihood of defective products making their way into the market.

Flexibility: Machine vision-based laser marking systems are highly versatile and can adapt to different product shapes and sizes. This versatility is invaluable in industries with diverse product portfolios.

Cost Savings: While the initial investment in machine vision technology may seem significant, the long-term cost savings are substantial due to reduced errors, increased throughput, and minimized rework.

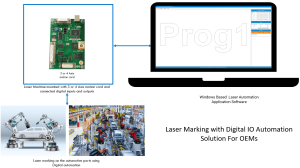

A Success Story: Our OEM partner Swastik Laser

One recent success story that illustrates the power of machine vision in laser marking comes from Swastik Laser. They specialize in manufacturing of wide range of laser marking and cutting solutions since more than a decade in many industries like automotive, dimond, Jwelry, manufacturing, consumer electronics and may more.

![panel-01[1] panel-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/panel-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![intranet-04[1] intranet-04[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/intranet-041-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![industrial-01[1] industrial-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/industrial-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)