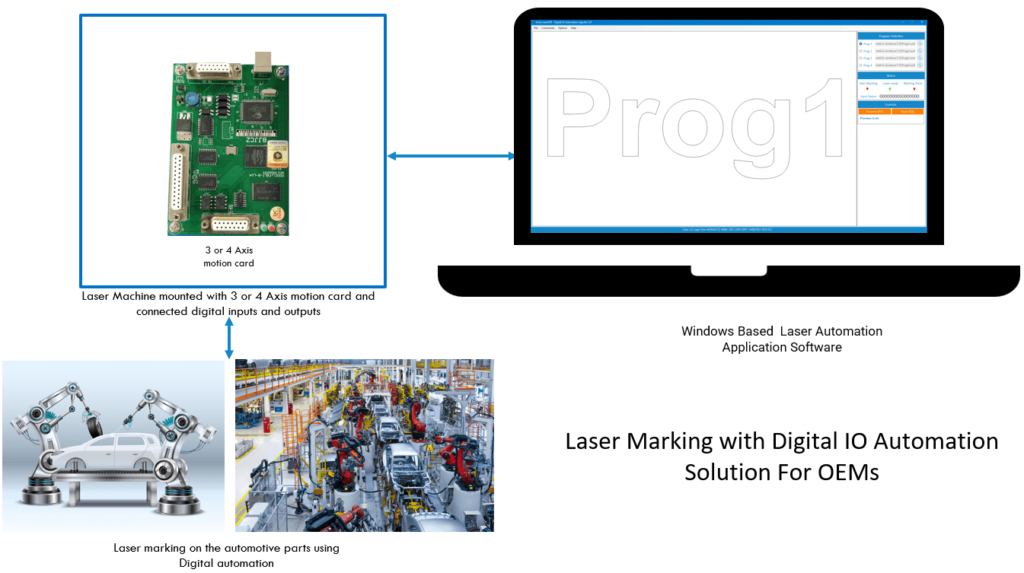

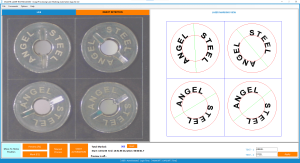

In manufacturing Industry 4.0, it will be always a time critical operation to save the OPEX cost. One of the important parameters is to perform laser marking on the different parts of the machine/object during manufacturing process and it should be automated to save the cost and time of the laser marking.

The project includes a system to have connection of Digital I/Os (8 or 16) in between existing PLC/HMI and digital automation laser marking software. It should also support the selection of multiple laser marking programs based on the automated input from the PLC/HMI. Synchronization between PLC and automation software plays a critical part to make smooth and effective laser marking using automation.

Thus, we have designed products with;

- Customization and white labeling

- Complete Desktop based and Touch based HMI software including control system (using PLC or Controller boards)

- High performance and real-time communication with the machine

- Multiple Program selection

- Support of multiple and configurable IOs

Solution:

- Supports 8 or 16 Digital I/Os to utilize during the automation process

- Multiple program selection based on configured digital input signals

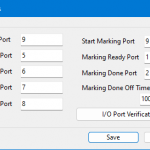

- Configurable input and outputs

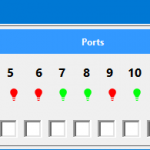

- Port test utility to check wire connection between PLC and card to help for the configuration of I/Os

- Synchronization of Start Marking, Laser Ready, and Marking Done signals between PLC and software

- Custom program selection to perform marking

Benefits

- Open wide range of possibilities to make laser marking process automated in large scale production environment

- Save OPEX cost because of automation of the laser marking and multiple program selection process

- Easy commissioning

![panel-01[1] panel-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/panel-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![intranet-04[1] intranet-04[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/intranet-041-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![industrial-01[1] industrial-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/industrial-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)