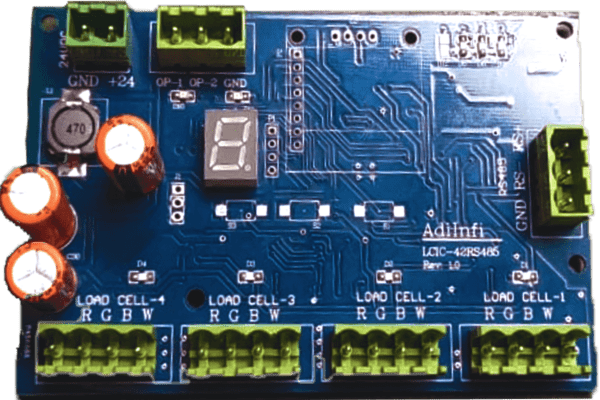

We have designed and developed generic card with 4 channel of individual ADCs to get better performance and 2 digital NPN outputs with Modbus-RTU protocol interface over RS485 to connect with HMIs and PLCs. It makes life easier to use this card in our customer’s industrial application to develop and integrate with their application.

We provide application customization as per customer need and provide in bulk quantity. For example, shown image of our product is getting used in our OEM customer’s application of fully Automatic Concrete Mixer Control panel. It supports dimension of panel rail mount.

We can also customize size and housing if required in quantity.

This card can be customized as per requirement of single or any multi channel ADC on a single card based on the production quantity

- 4 24-bits ADC channels with separate ADC chips

- 2 digital NPN outputs

- Two transistor output LEDs.

- Two Modbus LEDs: For activity on Rx, TX . Also shows any communication errors by having one LED continuously ON

- Eight loadcell LEDs: 1 if healthy and 0 for 0 voltage or any other issue

- First 8 Holding registers for 4 channel 24 bit Load cell data

- First 2 Coils for digital output

- Loadcell, temperature sensors, pressure gauge, current sensor, level sensor and many other 4 to 20mA supported sensors can be connected

- Card will continuously read 4 load cell 24 data and put in to first four holding registers

- Card will work as a Modbus slave device and get commands from PLC/HMI master

- In first two coils whatever data write command received from master, card will just write the same data to the respective Coil

- For any error or debugging, respective LEDs state can be verified

OEM Solution

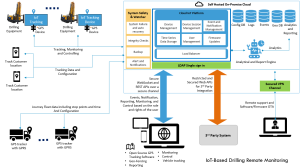

• We provide complete trunkey solution with help of our OEM partner

• we also provide separate 3-Axis hardware and Software solution to other OEM vendors

Faster Time to Market

Our Ready to use hardware, and software stack including Embedded OS, BSP, middleware layer, and reusable application layer and libraries helps to make it faster time to market.

PLC Panel Mounting Enclosure Design

To support Industry 4.0, We provide an enclosure with a PLC rack mounting option inside the panel. It is also possible to customize enclosure as per customer needs.

Specifications

Controller

STM32G030C8T6 – ARM Cortex M0 PLUS 64MHz controller

4 separate NAU7802 24 bit ADCs

0 to 3.3V Differential input

Conversion rate

10 samples per seconds. This can be optimized to 100 samples as per application need

Measurement accuracy

±0.05% (typical value)

Input voltage reverse connection protection and low-pass filter

Isolated RS485 10KV ESD protection

1 RS 485

For MODBUS-RTU protocol

2 digital NPN output

1 RS 232 TTL

Optional

0.96 Inch OLED display

Optional

4 ADC status LEDs

Communication health check LEDs

2 (Rx and Tx) RS485 status LEDs

Communication status and error

Power consumption

Less than 1W

Working temperature

0℃- +85℃. This can be achieved from -20℃ to +85℃ as per need.

Key Applications

Industry 4.0

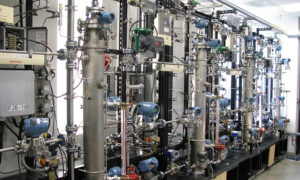

Industrial Automation uses Gateway to connect with devices and send data directly to the cloud, control, and monitor machines remotely using Cloud, Mobile, and Web applications.

Self Loading Concrete Mixer

Construction mixer like machines get big advantages to connect PLCs with Modbus and Control/Monitor whole machine from Cloud. Even it gives report of accuracy.

Retail

Smart retail devices like POS, price tags/smart shelves label can be build with the IoT gateway as a backbone to have quick performance and security.

![panel-01[1] panel-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/panel-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![intranet-04[1] intranet-04[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/intranet-041-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![industrial-01[1] industrial-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/industrial-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)