Business Needs

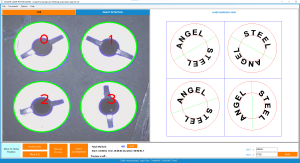

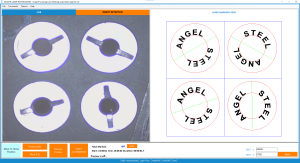

It was very hard to make precise laser marking by manually adjusting screws and very difficult especially when screws are with the drive(edge). Production becomes very slow and time consuming by manually adjust the screws and make laser marking. Customer of our OEM partner wanted to develop a complete automation solution to detect multiple screws, then detect edge(driver) or each crew, dynamically build template and perform laser marking. Target was to have x4 times production compare to manual process.

The project includes couple of challanges;

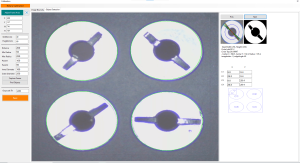

- Find an edge or screw head driver angle and according to that create laser marking template on runtime.

- System should not have any limitation of number of screws on the vision area.

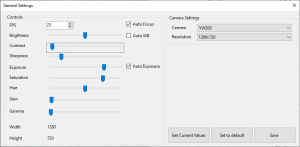

- Calibration of Visiona and Camera to create precised laser marking template in mili meter from specific camera angle and pixels ratio

- Rotary position and precision

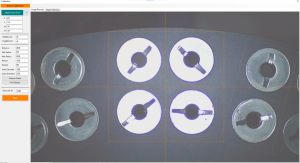

- Live camera macro view

Solution:

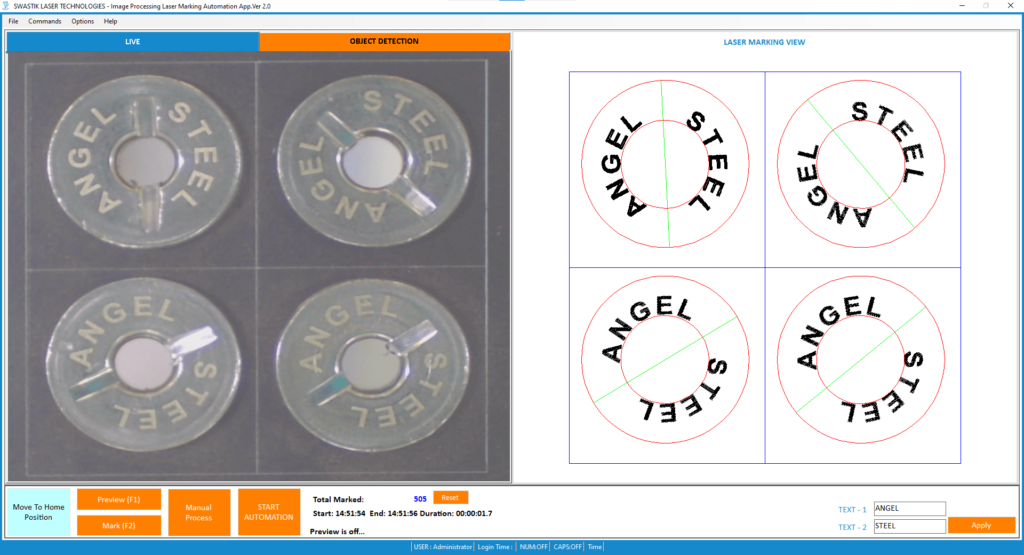

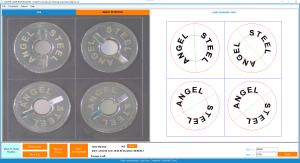

- Real time image processing using Machine (Computer) Vision

- Live macro camera view

- Manual laser marking

- 24×7 laser marking automation

- Customized marking template selection

- Easy calibration process of vision, laser and rotary

- Own IP algorithm for Screw edge or driver detection using Computer Vision

- Multiple program selection based on configured digital input signals

- Configurable input and outputs

- Port test utility to check wire connection

- Drive 3Axis Hardware to perform Laser marking

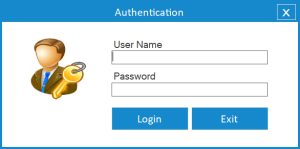

- Software user rights management

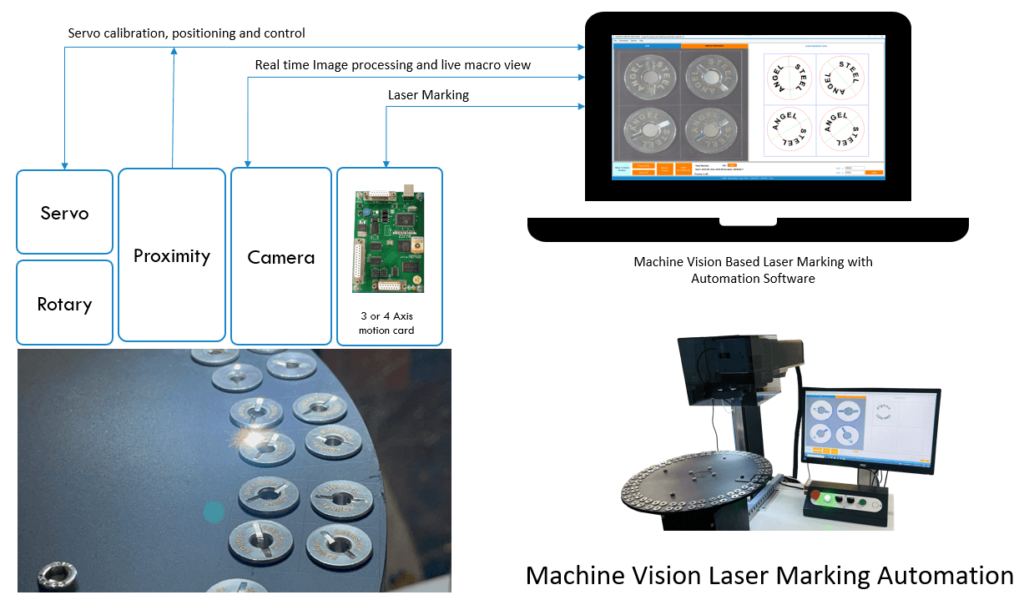

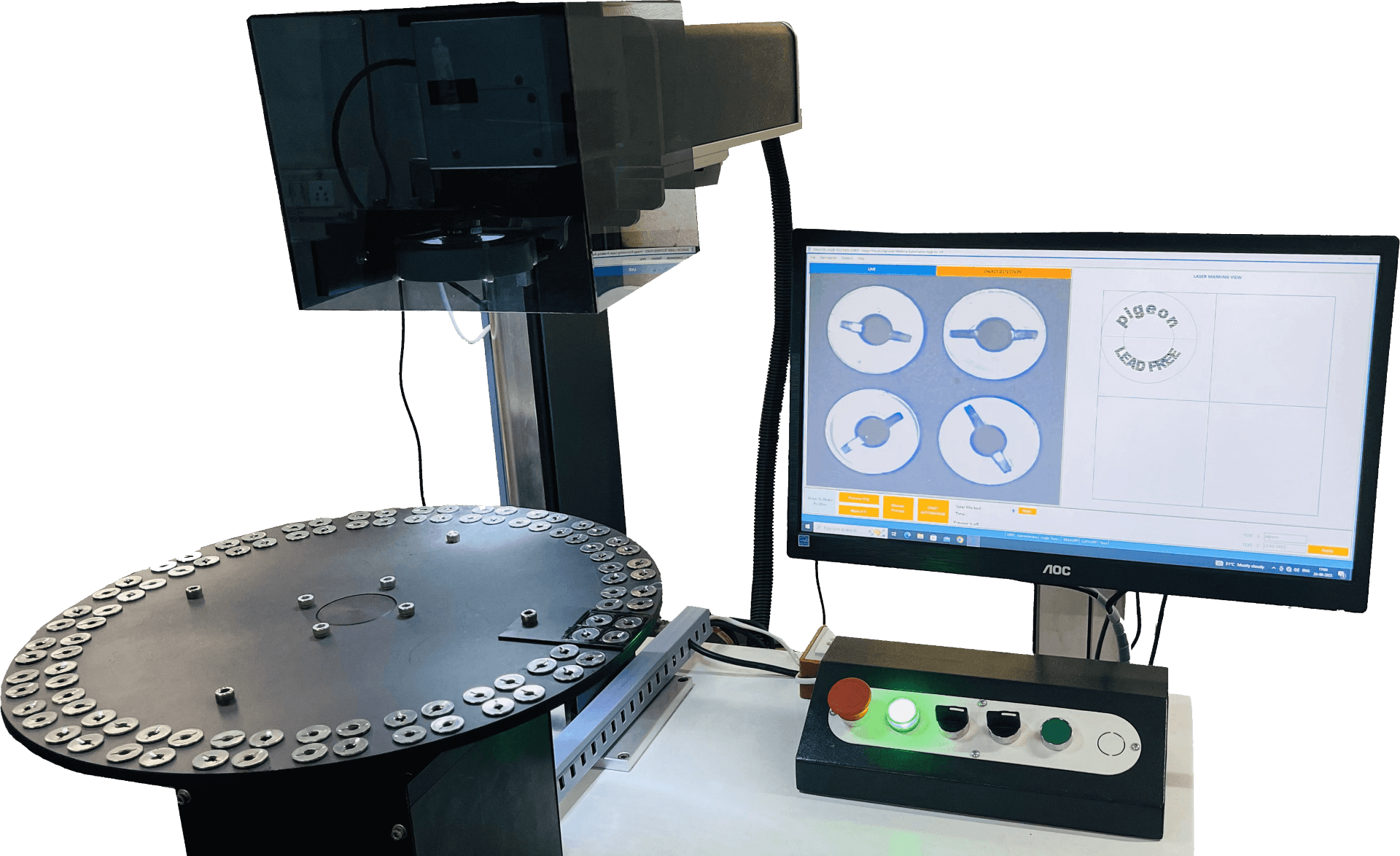

3Axis Hardware

- Hardware to communicate with our software application and to drive laser for the marking

OEM and Vendor support

- We provide complete trunkey solution with help of our OEM partner

- we also provide separate 3 or4-Axis hardware and Software solution to other OEM vendors

Benefits

- Open wide range of possibilities to make laser marking process automated using computer vision in large scale production environment. For current provided solution to our OEM, we have achieved more than 80K screws in 24 Hrs of automation. X8 times faster than manual process. This can be more based on laser marking parameters

- Save OPEX cost because of automation of the laser marking and computer vision

- Easy deployment and commissioning

- User friendly

Our OEM Partner

Ouer OEM partner’s Laser Machines mounted with the current solution

OEM Solution

• We provide complete trunkey solution with help of our OEM partner

• we also provide separate 3-Axis hardware and Software solution to other OEM vendors

Faster Time to Market

Our Ready to use hardware, and software stack including Embedded OS, BSP, middleware layer, and reusable application layer and libraries helps to make it faster time to market.

![panel-01[1] panel-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/panel-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![intranet-04[1] intranet-04[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/intranet-041-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![industrial-01[1] industrial-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/industrial-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)