MFI automation

The Melt Flow Indexer machine measures the rate of extrusion of a Thermoplastic Material through an orifice of Specific Length and Diameter under prescribed conditions of temperature and pressure. M.F.I Tester is used to measure the flow rate of different Polymers. The generated values help to distinguish the different grades of Polymers. Because of the fact that plastic materials are seldom manufactured without incorporating additives, which affect the processing characteristics of material like stability and flowing ability.

We provide a Microprocessor-based digital timer with the facility to select a number of tests, cutter time, buzzer indication on completion of the test, and advance buzzer indication for the manual cutting procedure. Fully Automatic MFI is having a facility to conduct the test independently by pre-setting the temperature(precise temperature with an accuracy of + 0.1º C) of the test, time & applying the required Load and it will directly give the result of MFI for individual test & average of all test.

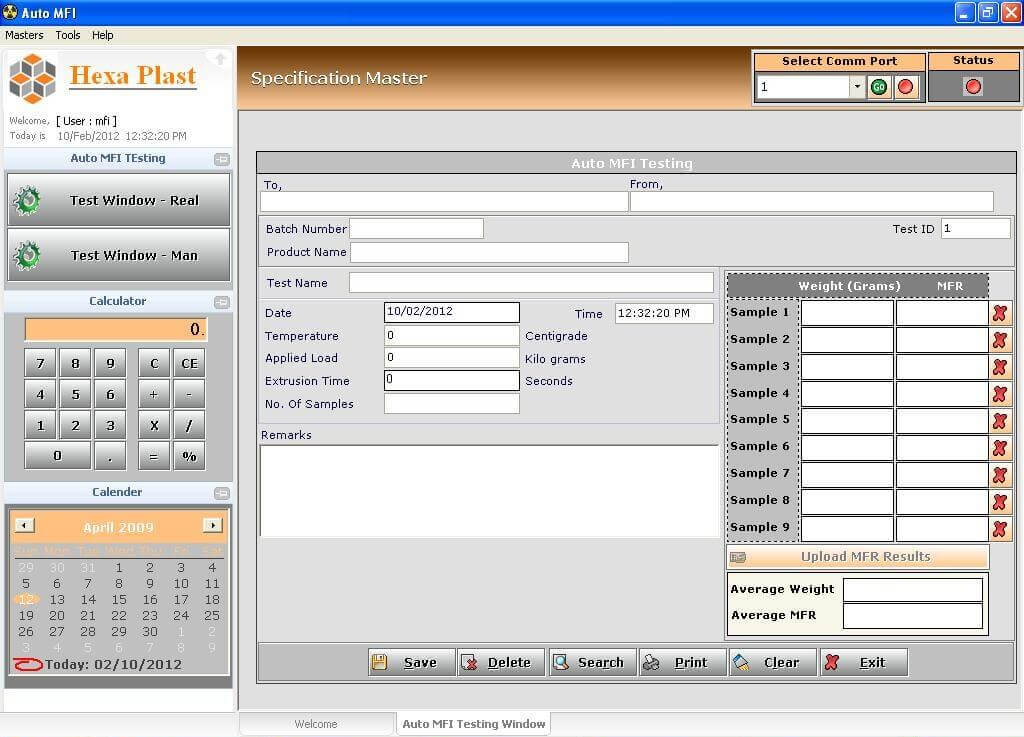

We provide complete computerized automation of the MFI using a Control Box and high-end computer desktop software. Refer to this video of our automated controller and software operation of the Auto MFI machine.

Key functionalities of Desktop Software and Controller:

- Graphic display with each controller and computer software

- Automatic Data capture and storage

- Recording of each test specifications, detailed results, analytical data, and retrieval using the search option

- Two-way communication between controllers and desktop application

- Auto COM port detection

- Company Logo customization facility for your end customers

- Print report and export to PDF

- Applying the required Load and will directly give the result of MFI for an individual test an average of all the tests

Our Offerings

OEM Solution

⮚ White labeling, customized enclosure, packaging, and connectivity options.

⮚ Which helps to save cost and time to market. We also help to set up support and maintenance channels.

Faster Time to Market

⮚ Our Ready to use controller hardware, HMI hardware, and desktop-based software helps to make it machine faster and more reliable to the market.

Technical Support and Training

⮚ We provide technical support and remote support to our OEM partners to make sure their end customers get an on-time solution in case of any technical issue.

⮚ We also provide training to our OEM customers so they can support their customers better.

Controller or HMI

⮚ We provide the controller with the LCD display or HMI with the PLC interface option based on the customer’s need.

Generic Desktop Software

⮚ Our software supports provided controller and HMI but we can also provide customization and integration of your own controller/HMI in case you already have a controller in-house at your end.

![panel-01[1] panel-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/panel-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![intranet-04[1] intranet-04[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/intranet-041-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![industrial-01[1] industrial-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/industrial-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)