Process

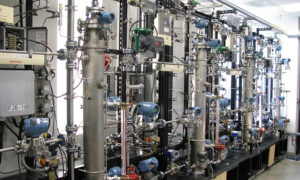

- The process industry relies heavily on a range of essential services to ensure smooth operations and optimal performance. This includes Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) to verify equipment functionality before and after installation.

- Supervision of Installation ensures that machinery and systems are set up correctly, while Loop Checking validates control loop functionality. System Commissioning ensures that all components work together seamlessly, guaranteeing efficiency and reliability.

- Additionally, services encompass Upgrade & Revamp of old systems, modernizing infrastructure for enhanced productivity. Selection, Sizing, Specification & Hook up Diagram of Field instruments ensure precise measurement and control.

- Legacy System Up-gradation brings older systems in line with current standards, while Breakdown Services provide swift resolution to unforeseen issues, minimizing downtime.

- These services collectively play a vital role in optimizing processes, ensuring safety, and driving operational excellence in the process industry

Advantages

- FAT & SAT ensure equipment functionality and compliance with specifications, minimizing risks and ensuring smooth deployment.

- Supervision of Installation guarantees correct setup, reducing errors and downtime.

- Loop Checking ensures the reliability of control systems, enhancing process control and safety.

- System Commissioning optimizes performance and efficiency from the outset.

- Upgrading and revamping old systems modernize infrastructure, improving productivity and competitiveness. Selection, Sizing, Specification & Hook up Diagram of Field instruments ensure accurate measurement and control, enhancing process efficiency and product quality.

- Legacy System Up-gradation extends the lifespan and functionality of existing systems, maximizing return on investment.

- Breakdown Services provide rapid response and resolution to equipment failures, minimizing disruptions and maintaining productivity. Collectively, these services contribute to operational excellence, safety, and profitability in various industries.

Our offerings

FAT & SAT

⮚ Factory Acceptance Test (FAT) and Site Acceptance Test (SAT) are crucial stages in the validation process of systems and equipment, particularly in regulated industries.

⮚ We provide the services to conduct FAT at the manufacturer's site to ensure the system meets predefined requirements before shipment & SAT at the installation site to confirm the system operates correctly in its working environment. These tests are essential for verifying that the equipment will function as intended and meet safety and quality standards, thereby minimizing the risk of faults during commissioning and operation.

Supervision of Installation

⮚ Supervision of installation services is a critical role that involves overseeing the entire process of setting up and installing various systems and equipment.

⮚ Our services include coordinating and supervising workers, ensuring adherence to safety standards, and maintaining quality control throughout the installation process. Our expertise ensures that installations go smoothly and efficiently, leading to reliable operation and maximum uptime for the systems installed. Installation supervisors are also responsible for training new employees and may be involved in project management tasks to ensure installations are completed on time and within budget.

Loop Checking

⮚ Loop checking is a critical process in the commissioning phase of industrial automation systems.

⮚ Our expert team of engineers are involved in verifying the proper functioning of the control loop, which includes all components from field sensors to the control system, ensuring they communicate correctly and perform as intended. This procedure is essential for maintaining the integrity of automated processes, as it helps identify and rectify any discrepancies in signal transmission, calibration, alarm settings, and other operational parameters. By conducting thorough loop checks, industries can ensure their systems operate reliably and efficiently, safeguarding against potential issues that could lead to downtime or safety hazards.

System Commissioning

⮚ System commissioning is a critical phase in the lifecycle of any project, involving a rigorous process of verifying that all systems and components are designed, installed, tested, operated, and maintained according to the operational requirements of the owner or final client.

⮚ Out expert team of engineers ensures the safe and orderly handover of the unit from construction to operation, guaranteeing performance, reliability, safety, and information traceability. This process is not only applicable to new projects but also to existing units and systems that are subject to expansion, renovation, or revamping.

Upgrade & Revamp of old systems

⮚ Upgrading and revamping old systems is a crucial aspect of maintaining efficiency, security, and competitiveness in any organization. Here's a general guide on how to approach such a project:

⬪ Assessment and Planning

⬪ Technology Selection

⬪ Implementation

⬪ Data Migration

⬪ Security Considerations

⬪ Monitoring and Maintenance

⬪ Documentation

⬪ Continuous Improvement

Selection, Sizing, Specification & Hook up Diagram of Field instruments

⮚ We have an expertise in the process of selecting, sizing, and specifying field instruments. It is critical to ensure the accurate and efficient operation of any industrial system.

⮚ It involves determining the right instruments based on the process variables they will measure and control, as well as the environmental conditions they will withstand.

Legacy System Up-gradation

⮚ System commissioning is a critical phase in the lifecycle of any project, involving a rigorous process of verifying that all systems and components are designed, installed, tested, operated, and maintained according to the operational requirements of the owner or final client.

⮚ Out expert team of engineers ensures the safe and orderly handover of the unit from construction to operation, guaranteeing performance, reliability, safety, and information traceability. This process is not only applicable to new projects but also to existing units and systems that are subject to expansion, renovation, or revamping.

Breakdown Services

⮚ Automation breakdown services are essential for maintaining the efficiency and reliability of automated systems.

⮚ Our expert service team provide rapid response and expert solutions to unexpected malfunctions or performance issues in automation systems.

⮚ We offer comprehensive support, from project planning and operations to emergency breakdown assistance, ensuring that automation systems remain operational and productive.

![panel-01[1] panel-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/panel-011-qzet7wibzvxnan2llc3lbke7tcjsob95xaavd6zpug.png)