UTM automation

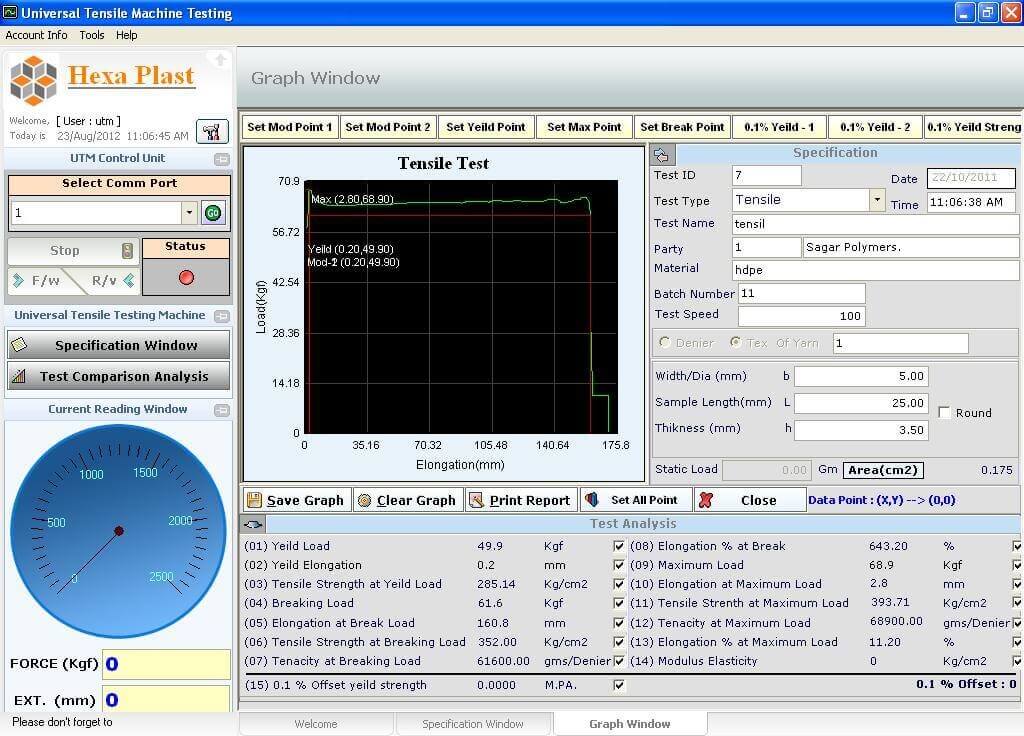

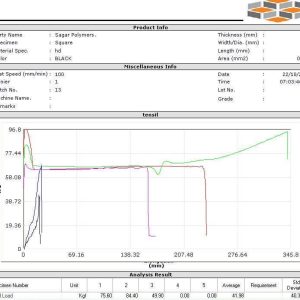

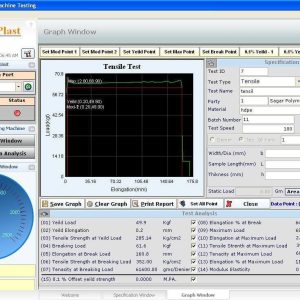

Universal Tensile Machine (UTM ) is a testing laboratory equipment for the universal test applied to many polymers to check the mechanical properties and it is the most important property as the majority of mechanical loading & properties like Tensile strength, modulus, elongation, compressive strength Etc. are calculated by using this machine.

We provide complete computerized automation of the UTM using a Control Box or HMI and high-end computer desktop software. Refer to this video of our automated controller and software operation of the UTM machine.

We provide customization of Software and Controller with white labeling for our OEM customers to use their branding.

Key functionalities of Desktop Software and Controller:

- Software and controller are universal for all different types of tensile Machines.

- Graphic display with the controller and computer software

- Automatic Data capture and storage

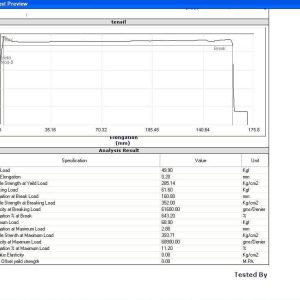

- Recording of each test specifications, detailed results, analytical data, and retrieval using the search option

- Online – Realtime display of load, extension, and graph view

- Online auto and fixed scalable graph

- Automatic detection and manual setpoint selection over the graph for Mod point 1, Mod point 2, Yield point, Max point, Breakpoint, and yield points

- Print report and export to PDF

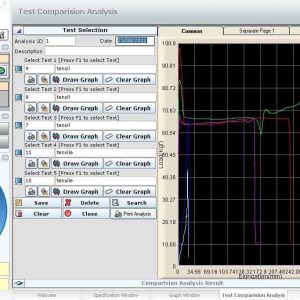

- Multiple test results graph comparison

- Load accuracy <0.5%

- Extension resolution 0.1 mm OR 0.01 mm

- Results in K.G./cm2 And Nt. mm2

- Auto COM port detection

- Yield Load

- Yield Elongation

- Tensile strength at Yield Load

- Breaking Load

- Elongation at Break Load

- Tensile strength at Breaking Load

- Tenacity at Breaking Load

- Elongation percentage at Break Load

- Maximum Load

- Elongation at Maximum Load

- Tensile strength at Maximum Load

- Tenacity at Maximum Load

- Elongation percentage at Maximum Load

- Modulus Elasticity

- 0.1% offset yield strength

- Two-way communication between controller and desktop application

Our Offerings

OEM Solution

⮚ White labeling, customized enclosure, packaging, and connectivity options. Which helps to save cost and time to market. We also help to set up support and maintenance channels.

Faster Time to Market

⮚ Our Ready to use controller hardware, HMI hardware, and desktop-based software helps to make it machine faster and more reliable to the market.

Technical Support and Training

⮚ We provide technical support and remote support to our OEM partners to make sure their end customers get an on-time solution in case of any technical issue.

⮚ We also provide training to our OEM customers so they can support their customers better.

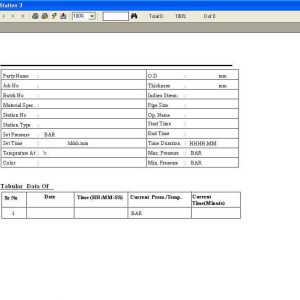

Controller or HMI

⮚ We provide the controller with the LCD display or HMI with the PLC interface option based on the customer’s need.

Generic Desktop Software

⮚ Our software supports provided controller and HMI but we can also provide customization and integration of your own controller/HMI in case you already have a controller in-house at your end.

![panel-01[1] panel-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/panel-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![intranet-04[1] intranet-04[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/intranet-041-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)

![industrial-01[1] industrial-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/industrial-011-qua2dyi8lke2c2fbaxb85dn8aq9qs3yz137rji5o60.png)