Variable Frequency Drives (VFDs) play a crucial role in the automotive industry by providing precise control over the speed and torque of electric motors used in various applications, such as conveyor systems, pumps, fans, and HVAC systems. Here’s a description of VFDs in the context of automotive industry precise speed regulation, soft starting and stopping, dynamic braking, overload protection, and seamless integration with automation systems.

Key Applications

FR-CS Series - CS80,

The FR-CS Series, including models like the CS80, refers to a range of frequency inverters or Variable Frequency Drives (VFDs) developed by Mitsubishi Electric. These inverters play a significant role in the automotive industry for controlling the speed and torque of electric motors used in various applications such as conveyor systems, pumps, fans, and HVAC systems. Here's a description of the FR-CS Series, particularly the CS80 model, in the context of the automotive

FR-D Series - D700

The FR-D Series, including models like the D700, refers to a range of compact and reliable frequency inverters or Variable Frequency Drives (VFDs) developed by Mitsubishi Electric. These inverters are commonly used in various industrial applications, including the automotive industry. Here's a description of the FR-D Series, particularly the D700 model, in the context of the automotive industry

FR-E Series - E700, E800

The FR-E Series, represented by models like the E700 and E800, is a versatile lineup of frequency inverters or Variable Frequency Drives (VFDs) designed by Mitsubishi Electric. These inverters find extensive applications in the automotive industry, offering a range of features tailored to meet the specific needs of automotive manufacturing processes.

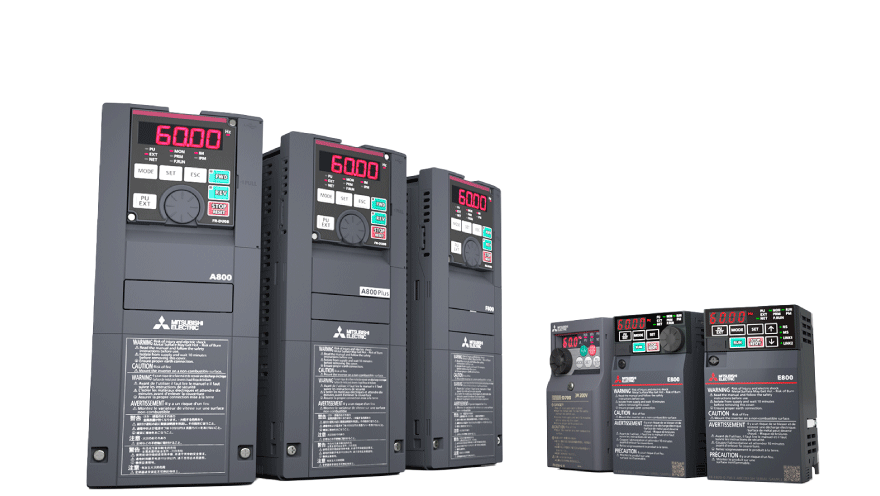

FR-A Series – A800

The FR-A Series, exemplified by the A800 model, stands as a flagship lineup of frequency inverters or Variable Frequency Drives (VFDs) developed by Mitsubishi Electric. These inverters are pivotal in the automotive industry for regulating motor speed and torque in various applications, including conveyor systems, pumps, fans, and machine tools. Here's an in-depth description of the FR-A Series, with a focus on the A800 model, in the context of automotive manufacturing

Key functionalities of IoT Gateway

- Establishing a communication bridge between devices and the cloud

- Provides additional security

- Performs data aggregation and logging

- Pre-processing and filtering of data

- Provides local storage to store and cache data

- Data computing at the edge level

- Ability to manage the entire device

- Device diagnostics

- Adding the more functional capability

Working of IoT Gateway

- Receives data from the sensor network using RS232, RS485 Modbus, USB, SPI, I2C etc

- Performs Preprocessing, filtering, and cleaning on unfiltered data

- Transports into standard protocols for communication

- Sends data to the cloud over MQTT

OEM Solution

• We provide complete trunkey solution with help of our OEM partner

• we also provide separate 3-Axis hardware and Software solution to other OEM vendors

Faster Time to Market

Our Ready to use hardware, and software stack including Embedded OS, BSP, middleware layer, and reusable application layer and libraries helps to make it faster time to market.

PLC Panel Mounting Enclosure Design

To support Industry 4.0, We provide an enclosure with a PLC rack mounting option inside the panel. It is also possible to customize enclosure as per customer needs.

![panel-01[1] panel-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/panel-011-qzet7wibzvxnan2llc3lbke7tcjsob95xaavd6zpug.png)