Project Engineering & Documentation

Successful project delivery, no matter what the challenges are.

Effective documentation is essential for tracking progress, ensuring that projects are executed in an organized manner, and facilitating the replication of past successes while avoiding previous failures. Proper documentation practices can significantly contribute to a project’s success by providing a clear and detailed method for organizing essential documents and information.

Process

- Project Engineering and Documentation is a critical process that involves the creation and management of a project’s technical and administrative records.

- It encompasses the development of detailed process documents that guide the execution of a project from inception to completion.

- This includes defining the project scope, objectives, and deliverables, as well as outlining the steps and resources required to achieve the project goals.

- Effective documentation ensures that all project stakeholders are aligned and can contribute to the project’s success efficiently and cohesively.

Advantages

- Project Engineering and Documentation are critical aspects of successful project management, offering numerous advantages.

- Effective documentation acts as a roadmap, guiding project teams through the complexities of development and ensuring that all members have a clear understanding of tasks and objectives.

- It also serves as a communication bridge, enhancing collaboration and reducing misunderstandings among stakeholders.

- Furthermore, well-organized documentation can improve efficiency by streamlining processes, which in turn can lead to a higher success rate and better deliverable quality.

- By maintaining a detailed record of the project’s evolution, documentation helps in preserving essential knowledge and mitigating the risk of information loss. .

Our offerings

MDL – Master Document List

⮚ A Master Document List (MDL) is a comprehensive list that includes key details about each document within a project or organization

⮚ Drawing/Document Name

⮚ Drawing/Document Number

⮚ Revision number

⮚ Approval Status

Bill of Material

⮚ A Bill of Materials (BOM) is a comprehensive list that outlines the components and materials required for the project execution.

⮚ Item Name

⮚ Item Description / Specification

⮚ Make & Model No.

⮚ Quantity

Layout Drawing

⮚ Creating a detailed layout drawing for a process plant involves a comprehensive understanding of the plant's operations, machinery, and workflow.

⮚ The layout should optimize the flow of materials and personnel, minimize equipment and process bottlenecks, and adhere to safety standards.

Item / Instrument Technical Datasheet

⮚ A technical datasheet for an instrument is a comprehensive document that provides all the necessary details about the equipment's features and specifications.

⮚ It typically includes information such as the instrument's tag number, product name, model number, service description, location, P&ID number, and detailed technical specifications like measurement range, accuracy, resolution, and precision.

⮚ Additionally, it outlines that the instrument meets the key parameters of the process it is intended for.

Instrument Hookup Drawing

⮚ Instrument Hookup Drawings are essential documents in the engineering field, detailing the complete installation process of instruments.

⮚ They specify the scope of work between Mechanical and Instrumentation departments and ensure that instruments are installed correctly to operate properly.

⮚ These drawings include information on the tag number, the bill of materials, the type of material based on fluid parameters, and the position of the instrument in reference to the process tapping point.

Instrument Index

⮚ An Instrument Index is a crucial document in the process industry that lists all instruments and devices used within a facility, providing key details such as type, location, function, manufacturer, and model number.

⮚ This index serves as a comprehensive reference for maintenance, repair, and calibration activities, ensuring that all instrumentation is accounted for and properly managed.

Quality System Documentation

Quality System Documentation is a critical aspect of ensuring that equipment, systems, and processes meet the necessary standards and function as intended.

where we provide:

⮚ DQ: Design Qualification

⮚ IQ: Installation Qualification

⮚ OQ: Operational Qualification

⮚ FAT: FAT at our Workshop

⮚ SAT: SAT at Customer Site

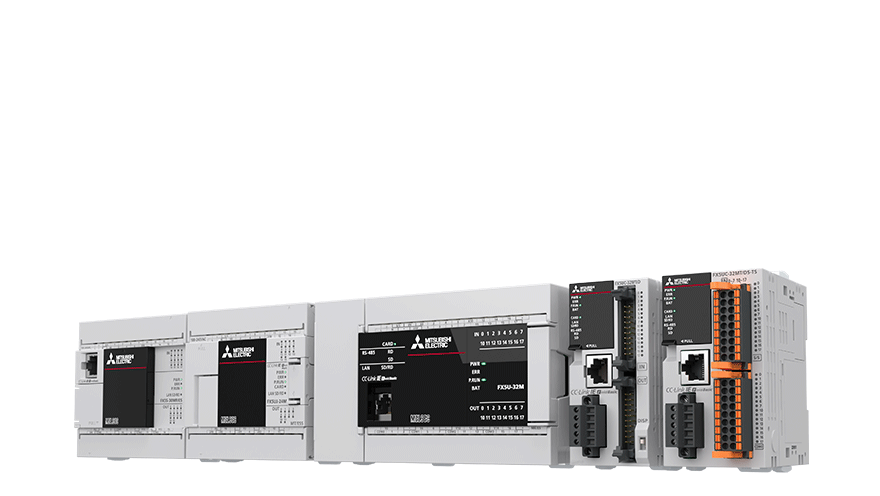

Control System Documentation

Control System Documentation is a critical aspect of industrial automation and control systems engineering.

where we provide:

⮚ IO List with Point Assignment

⮚ Alarm List (Process & System)

⮚ Hardware Design Specification

⮚ Software Design Specification

⮚ Functional Design Specification

⮚ Computer System Validation

Control Panel Documentation

Control panel documentation is essential for the design, operation, and maintenance of electrical systems.

where we provide:

⮚ GA (General Arrangement) Drawing

⮚ LA (Lay Arrangement) Drawing

⮚ PD (Power Distribution) Drawing & Single Line Diagram

⮚ CW (Control Wiring) Drawing

⮚ JB Schedule

⮚ Loop Drawing.

PLC & SCADA Validation

In the field of industrial automation, PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) systems are crucial for ensuring operational efficiency and safety.

The validation process typically involves several key steps:

⮚ Starting with a

GxP (Good x Practices) assessment to ensure compliance with industry standards, followed by the creation of a System Requirement Specification (SRS) to outline the necessary system capabilities.

⮚ Pre-Functional Risk Assessment (Pre-FRA) is conducted to identify potential risks before they occur.

⮚ Installation Qualification (IQ) and Operational Qualification (OQ) are then performed, along with their respective reports (IQR and OQR), to verify the correct installation and operation of the system.

⮚ Post-Functional Risk Assessment (Post-FRA) is carried out to evaluate the system after it has been put into operation.

⮚ These steps are essential to maintain the integrity and reliability of PLC and SCADA systems in various industries.

![panel-01[1] panel-01[1]](https://eleetpro.com/wp-content/uploads/elementor/thumbs/panel-011-qzet7wibzvxnan2llc3lbke7tcjsob95xaavd6zpug.png)